WHEAT:NEWS June 2024 Volume 15, Number 6

WBEZ HAD BIG PLANS

You’re going to need a sharp axe to cut through all the details of budgeting for new AoIP studios. The number of channels, microphones, drivers, sources and where GPIO will be used and for what–everything needs to be thought out well in advance to avoid cost overruns.

Here’s how we helped WBEZ FM, Chicago, sharpen the axe for new WheatNet studios.

Long before Chicago Public Media cut over from its legacy TDM routed studios to a WheatNet® IP audio networked facility in December 2023, there was a plan.

It began years before when our senior sales engineer Jay Tyler stopped in to do a walkthrough of the WBEZ 91.5 facility on Chicago’s Navy Pier. (Read Extreme Studio Makeover in last month’s Wheat News.)

One of the more prolific NPR stations in the country, where iconic shows like Wait Wait…Don’t Tell Me and This American Life have been created and with live local shows such as Reset with Sasha Ann-Simons, WBEZ had been using Wheatstone’s TDM network and consoles since 1995.

Cutting through decades of add-on infrastructure and getting the most out of AoIP networking would take a sharp axe.

“When you go with an AoIP system it’s a little bit different than the traditional analog systems where channel counts, number of microphones, number of drivers, analog/digital sources, even down to the GPIO all should be spec’d ahead of time [to avoid cost overruns],” said Tyler, who drew up an initial layout for WBEZ’s new studios soon after he returned to New Bern from Chicago.

The goal from the start was to establish better sight lines between studios, greater usability of each studio and the ability to create video while establishing a standard studio footprint that flowed from one workspace to the next.

Tyler’s layout outlined AoIP elements, signal flow and logic controls optimized for eight primary studios and four production rooms. With input from Andy Cole at SCMS, the CAD drawing included mics and other accessories in addition to WheatNet IP audio routing, console surfaces, talent stations, and topology.

Tyler’s layout outlined AoIP elements, signal flow and logic controls optimized for eight primary studios and four production rooms. With input from Andy Cole at SCMS, the CAD drawing included mics and other accessories in addition to WheatNet IP audio routing, console surfaces, talent stations, and topology.

The pandemic came and went and planning continued. Chicago Public Media Vice President of Technology and Operations Stephen Wright sat down with 15 staff members representing anchors, producers, and hosts to go over potential designs and workflows. Architect firm V Three Studios from St. Louis began drafting a new studio core for a more workflow friendly environment.

"Give me six hours to chop down a tree, and I will spend the first four sharpening the axe.”

"Give me six hours to chop down a tree, and I will spend the first four sharpening the axe.”

― Abraham Lincoln

Wright continued the collaborative planning and brought in other consoles and routing systems in addition to WheatNet IP for evaluation by the “people who would actively be using the system every day.” The consensus was to go with WheatNet IP audio networking and LXE console surfaces, and a more detailed plan began to emerge.

Adding to the project team were local general contractor Skender, which had experience with the construction logistics of Navy Pier, and systems integrator Inrush Broadcast Services, whose engineers had worked at WBEZ at various points in their broadcast careers.

Inrush engineers scripted workflow screens into studios as well as framed out the AoIP infrastructure according to plan. “By the time we got involved the equipment list was finalized, down to the inputs and outputs,” said Inrush’s Shaun Dolan.

Given their long history with the studios, removing all the cabling from the old TOC was a personal victory for Dolan and fellow Inrush partners Mike Dorris and Brian Sapp. “Being able to go from the terminal room, which was always a bit touchy to work in with legacy wiring and equipment, to the new simple TOC with everything done in software over a few cables … was really satisfying,” commented Dolan.

The rest went according to plan and to budget, with the team working off a detailed drawing laying out eight LXE consoles in main on-air rooms and master control; four L Series consoles in production rooms; 42 talent stations for talk positions throughout; and 63 I/O Blades with hundreds of channels of GPIO and more than 1,000 crosspoints connecting all 12 studios and dozens of workflows.

Each source, destination, user interface, and workflow was planned and accounted for, effectively eliminating downtime as well as cost overruns over the life of the project.

Behind the camera in these photos are Bob Martin, a regular WBEZ listener and a longtime friend and associate of Wheatstone, and his son Nick Gerber, a videographer who spent the day touring the new WBEZ facility.

Starting a new studio project? Download our helpful guide Studio Project Planning for trends to consider and gotchas to avoid.

FACTORY WALKTHROUGH (SHOES OPTIONAL)

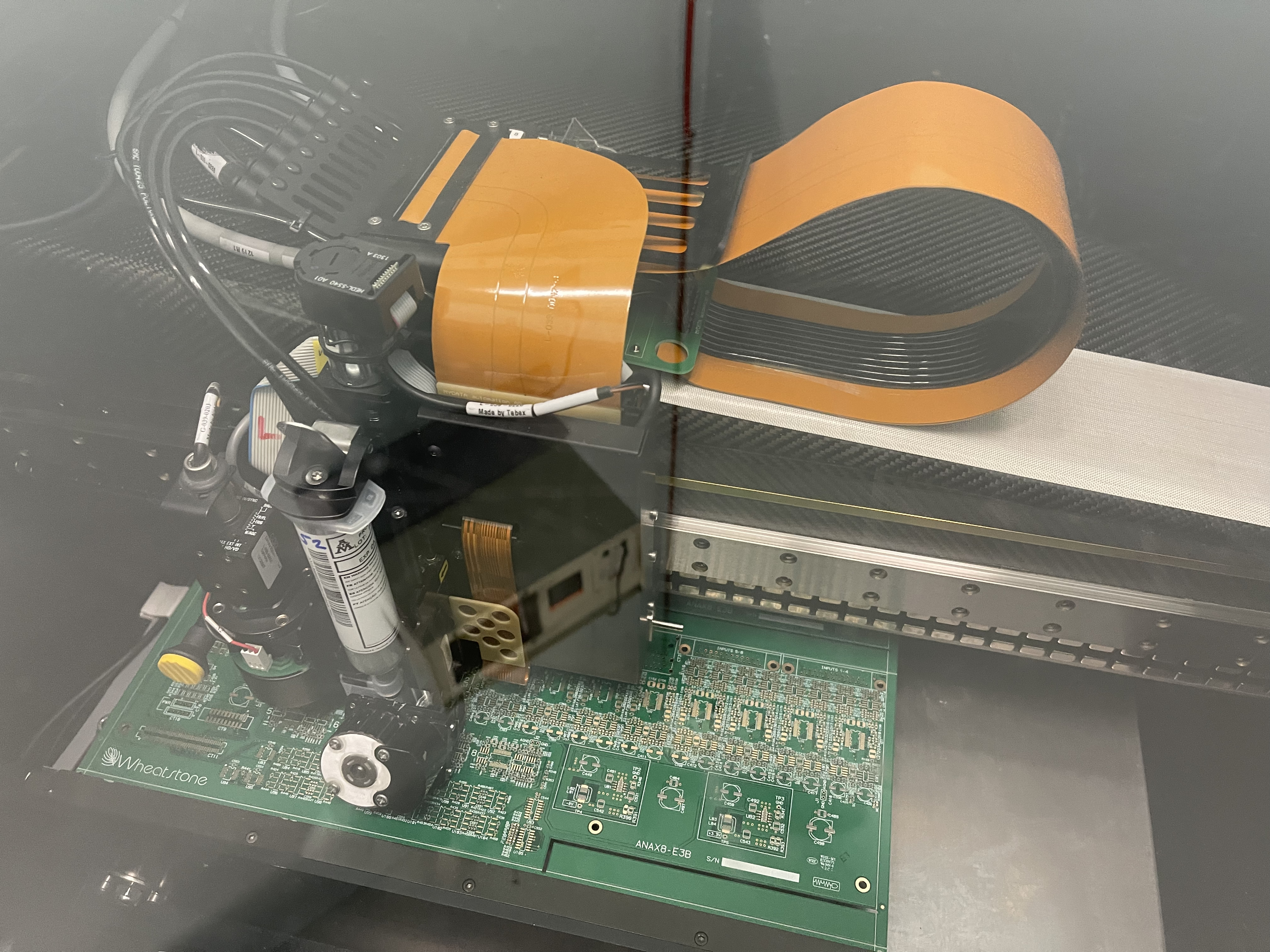

It comes in one end as metal, electronic components and other raw materials and emerges out the other as consoles, talent stations, I/O Blades and audio processors. Here’s a quick virtual walkthrough of the magic that takes place every day in the Wheatstone factory in New Bern, North Carolina.

Shown, Darrin Paley, Wheatstone senior sales engineer, holding a Blade 3 that just came off the press. The computerized press machine behind him is a recent addition to the factory and can press Blade panels in hours instead of what used to take days.

Shown, Darrin Paley, Wheatstone senior sales engineer, holding a Blade 3 that just came off the press. The computerized press machine behind him is a recent addition to the factory and can press Blade panels in hours instead of what used to take days.

Wheatstone panels go through a powder coat paint process with the labels etched in, which achieves far better durability compared to traditional silkscreen techniques.

Machines like this one are the beating heart of electronics production at Wheatstone. Dozens of components are mounted directly onto the surface of printed circuit boards in one sweep to make Wheatstone and Audioarts consoles and Blades.

An overhead view of the soldering machine.

Finished surface mount cards are inspected photographically by this dedicated computer with specialized high-resolution camera and software, which detects solder failures or bridged components. The card is photographed in segments, as shown, and even the slightest error is highlighted for correction.

Finished surface mount cards are inspected photographically by this dedicated computer with specialized high-resolution camera and software, which detects solder failures or bridged components. The card is photographed in segments, as shown, and even the slightest error is highlighted for correction.

Wheatstone sources and stores components needed for more than 200 broadcast products currently in production as well as products now in service in studios worldwide. This 5,000- square-foot stockroom contains rows of parts that go all the way to the ceiling.

To schedule a real walkthrough of the Wheatstone factory, contact our sales team at sales@wheatstone.com.

AoIP ISN’T THE ONLY NETWORKING GOING ON IN THE WHEAT LAB

Shown, the Bonneville “Dream Team” of engineers during a recent visit to the Wheatstone factory where they explored new ways of enhancing their operations using WheatNet IP audio tools. The team flew in from San Francisco, Sacramento, Salt Lake City, Denver, and Phoenix and was joined by Nate Mumford at RCS, who spent time discussing Zetta & Zetta2GO enhancements as part of the WheatNet IP audio environment. (Read about Bonneville, 100 Studios Later.)

The Wheat Lab is also where we stage, preconfigure and test multi-studio systems before shipping to their final destinations as plug-in ready systems. The Lab is located just a few steps away from where we engineer, manufacture, and support the 200+ AoIP elements that make up the WheatNet IP audio network.

AoIP Q&A: HURRICANE SEASON 2024 IS EXPECTED TO BE A DOOZY. WHAT’S AN AOIP TO DO?

Q: We just heard that NOAA is predicting an intense 2024 hurricane season. We have several locations in Hurricane Alley. How can we prepare?

A: We hear you! Being in North Carolina, we have a special appreciation (and apprehension) for hurricane season. That’s one good reason why we decided to go the distributed network route when designing the WheatNet IP audio network. With audio tools, routing and control at every connection point, if one part of the WheatNet IP network fails for any reason, the rest can keep on functioning. Each I/O Blade not only stores its configuration but also the entire configuration of the network, which can be very helpful when preparing for hurricane season.

One simple thing you can do is to add or move a spare I/O Blade from the studio to the transmitter site. A Blade at each transmitter site can be especially useful as a final workaround in an emergency because it has silence detection, flexible GPI logic, salvo programming, and in the case of our newer Blade 4, audio codecs built in.

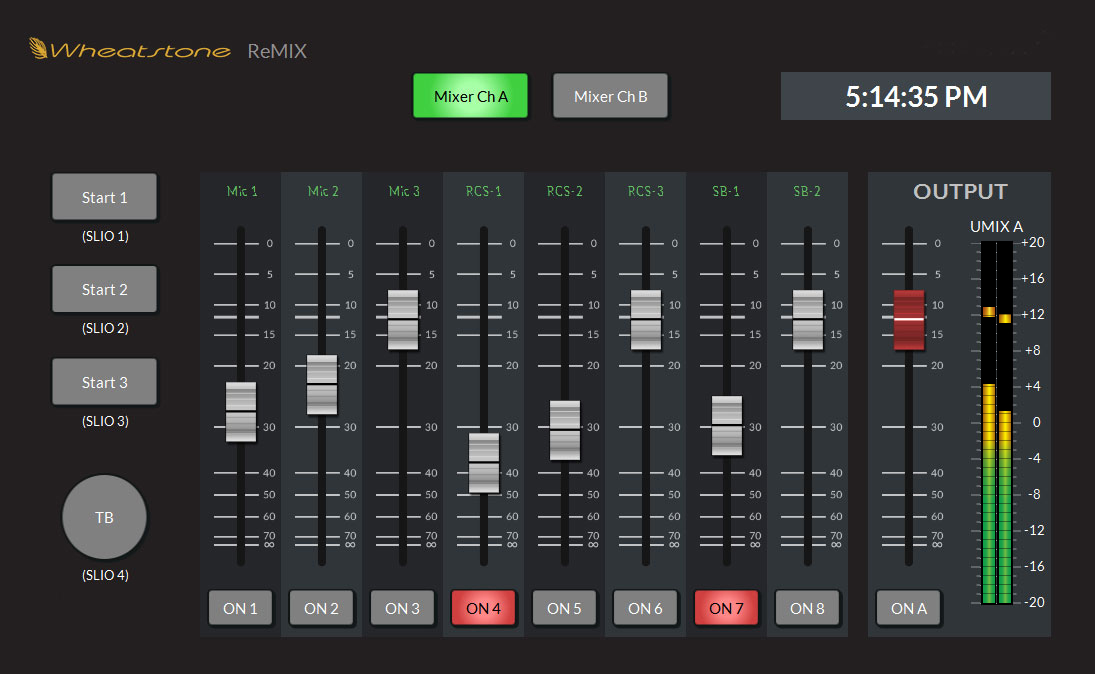

Interconnecting all your locations together is the next obvious move. Should one studio or transmitter get hit by disaster, you can continue emergency updates from any other studio location and/or switch to other transmitters in your interconnected network. We also suggest establishing remote access to the studio by key employees and technology partners as an emergency backup, if you haven’t done so already. There are now many affordable remote apps available for this purpose (ask us about ReMIX).

Finally, we suggest you set up a backup audio player at each transmitter site to broadcast an emergency audio loop in case your studio is down. This can be a regular recorder rigged to turn on in an emergency (which can be triggered by silence detection via a Blade), or it could be a clip player in a Blade (note, not all Blades have a clip player so if you’re repurposing an I/O Blade from the studio to the transmitter site, pick one that has the clip player option).

There are many creative ways to configure Blades for disaster recovery. Tell us how you’re using Blades in your disaster recovery plan and we’ll send you a Wheatstone ball cap. Email Dee McVicker at dee@wheatstone.com.

There are many creative ways to configure Blades for disaster recovery. Tell us how you’re using Blades in your disaster recovery plan and we’ll send you a Wheatstone ball cap. Email Dee McVicker at dee@wheatstone.com.

TECH TIP: MAKING THE AUTOMATION-TO-RDS CONNECTION

RDS/RBDS encoders in audio processors such as our MP-532 FM/AM/HD multiprocessor and Audioarts LiON receive song data and other messaging from the automation system via Ethernet using UDP packets. If you have an older automation system that only transmits serial data, our technical support engineer John Davis suggests converting RS-232 data into UDP using software such as Serial to Ethernet Connector. (In a multi-station operation, be sure to use unique UDP ports for each automation PC so you don’t send the wrong artist/title information to the wrong station.)

Automation systems also send data formatted in one of four ways: UCEP Strict, UECP Unpacked, Plain Text PS, or Plain Text RT. Details of each and to get a list of RDS formats by automation system and other information, download our application note Automating RDS With the MP-532 Audio Processor.

NOW AND THEN

Will Bevis is a long-time friend of Wheatstone consoles. Here he is today in front of an Audioarts DMX console at WCWT 107.3 in Centerville, Ohio. Here he is again in 1986, seated at a Wheatstone A32 console at WGTZ (Z93) Dayton.

Bevis started out at WCWT in 1971 when he was just 11 years old and spent the next 20 years in radio and television following college.

Bevis started out at WCWT in 1971 when he was just 11 years old and spent the next 20 years in radio and television following college.

When he started in broadcasting, WCWT operated out of a middle school restroom before moving to Centerville High School in 1975, where it remains today. “I left broadcasting 27 years ago but came back and raised money for the school and then had to figure out what a Wheatstone DMX was…. incredible piece of equipment,” Bevis commented.

WCWT has been on the air for 53 years. The LPFM has three DMX consoles. Shown, below, is a DMX 8 in production room B, which also has our Quickline furniture.

WCWT has been on the air for 53 years. The LPFM has three DMX consoles. Shown, below, is a DMX 8 in production room B, which also has our Quickline furniture.

For our Wheatstone history buffs, the A32 was manufactured in the late 1980s through early 90s. We still maintain modules for supporting this and other products made during that time. In fact, here’s an A32 module we pulled from our stockroom recently.

For our Wheatstone history buffs, the A32 was manufactured in the late 1980s through early 90s. We still maintain modules for supporting this and other products made during that time. In fact, here’s an A32 module we pulled from our stockroom recently.

Interesting Links:

The Wheatstone online store is now open! You can purchase demo units, spare cards, subassemblies, modules and other discontinued or out-of-production components for Wheatstone, Audioarts, and VoxPro products online, or call Wheatstone customer support at 252-638-7000 or contact the Wheatstone technical support team online as usual.

The store is another convenience at wheatstone.com, where you can access product manuals, white papers and tutorials as well as technical and discussion forums such as our AoIP Scripters Forum.

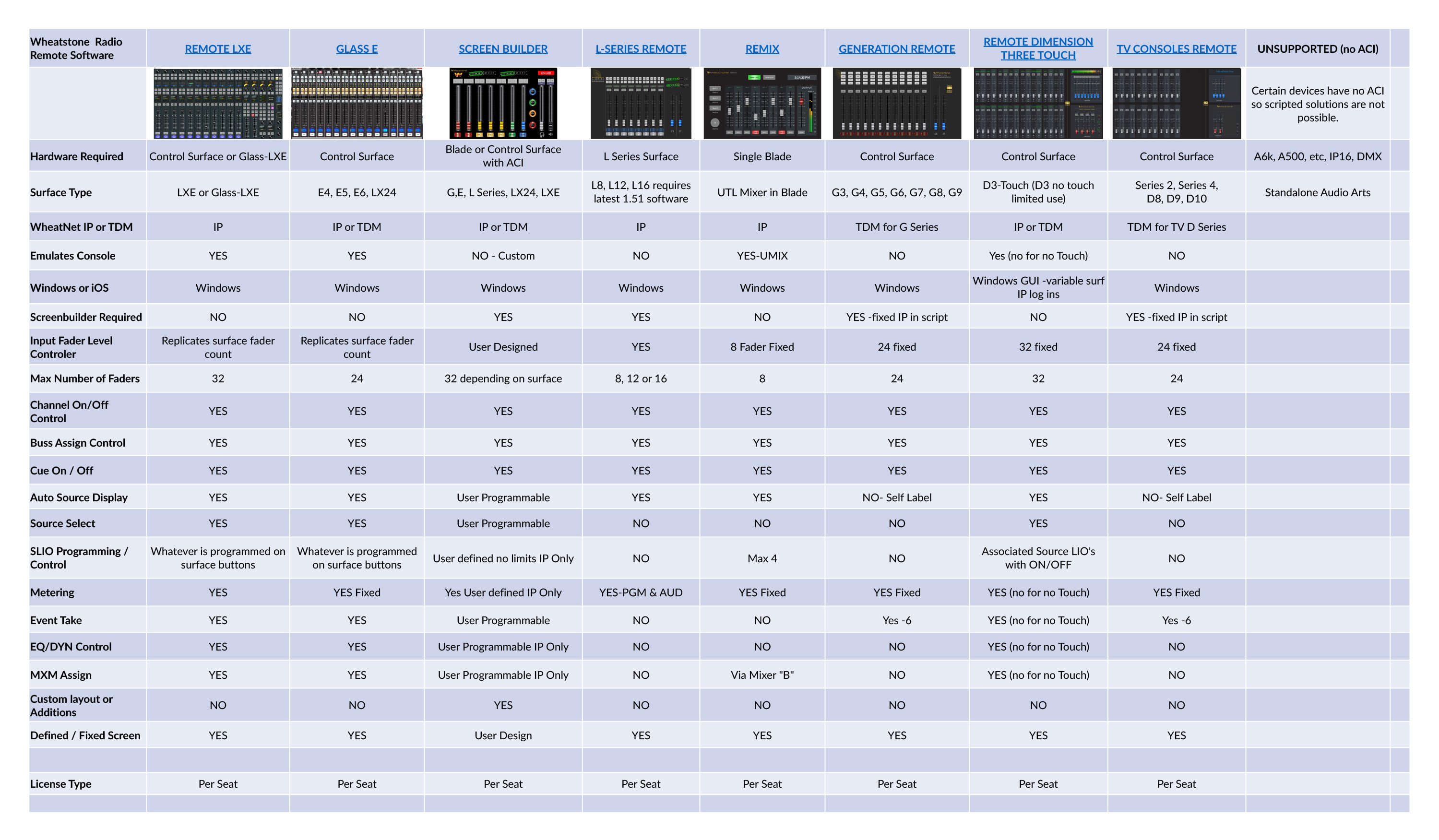

Compare All of Wheatstone's Remote Solutions

We've got remote solutions for virtually every networkable console we've built in the last 20 years or so. For basic volume, on/off, bus assign, logic, it's as easy as running an app either locally with a good VPN, or back at the studio, using a remote-access app such as Teambuilder to run.

We've got remote solutions for virtually every networkable console we've built in the last 20 years or so. For basic volume, on/off, bus assign, logic, it's as easy as running an app either locally with a good VPN, or back at the studio, using a remote-access app such as Teambuilder to run.

Remote Solutions Video Demonstrations

Jay Tyler recently completed a series of videos demonstrating the various solutions Wheatstone offers for remote broadcasting.

Check out the chart below, and/or click here to learn more on our Remote Solutions web page.

Studio Project Planning Guide

Studio Project Planning Guide

EVERYTHING YOU NEED TO KNOW FOR MAKING YOUR STUDIO PROJECT A SUCCESS

Have you seen the latest smart studio trends? Discover expert tips, surprising uses for AoIP Blades, 6 common studio gotchas, and how to be aware of little expenses. A must-read before you begin your studio project.

Making Sense of the Virtual Studio

Making Sense of the Virtual Studio

SMART STRATEGIES AND VIRTUAL TOOLS FOR ADAPTING TO CHANGE

Curious about how the modern studio has evolved in an IP world? Virtualization of the studio is WAY more than tossing a control surface on a touch screen. With today's tools, you can virtualize control over almost ANYTHING you want to do with your audio network. This free e-book illustrates what real-world engineers and radio studios are doing. Pretty amazing stuff.

IP Audio for TV Production and Beyond

IP Audio for TV Production and Beyond

WHAT YOU NEED TO KNOW ABOUT MANAGING MORE CHANNELS, MORE MIXES, AND MORE REMOTE VENUES

For this FREE e-book download, we've put together this e-book with fresh info and some of the articles that we've authored for our website, white papers, and news that dives into some of the cool stuff you can do with a modern AoIP network like Wheatstone's WheatNet-IP.

Got feedback or questions? Click my name below to send us an e-mail. You can also use the links at the top or bottom of the page to follow us on popular social networking sites and the tabs will take you to our most often visited pages.